In the world of industrial filtration, efficiency, reliability, and durability are key factors that determine the success of filtration systems. Among the numerous options available, PP wound filter cartridges and quality filter housing have emerged as some of the most effective components used in industries today. These products offer multiple benefits, from high filtration accuracy to cost-effective operation, making them a popular choice for industries like pharmaceuticals, food and beverage, chemicals, and water treatment.

In this blog, we’ll explore the numerous benefits of using PP wound filter cartridges with quality filter housing and why they are essential for any high-performance filtration system.

1. What are PP Wound Filter Cartridges?

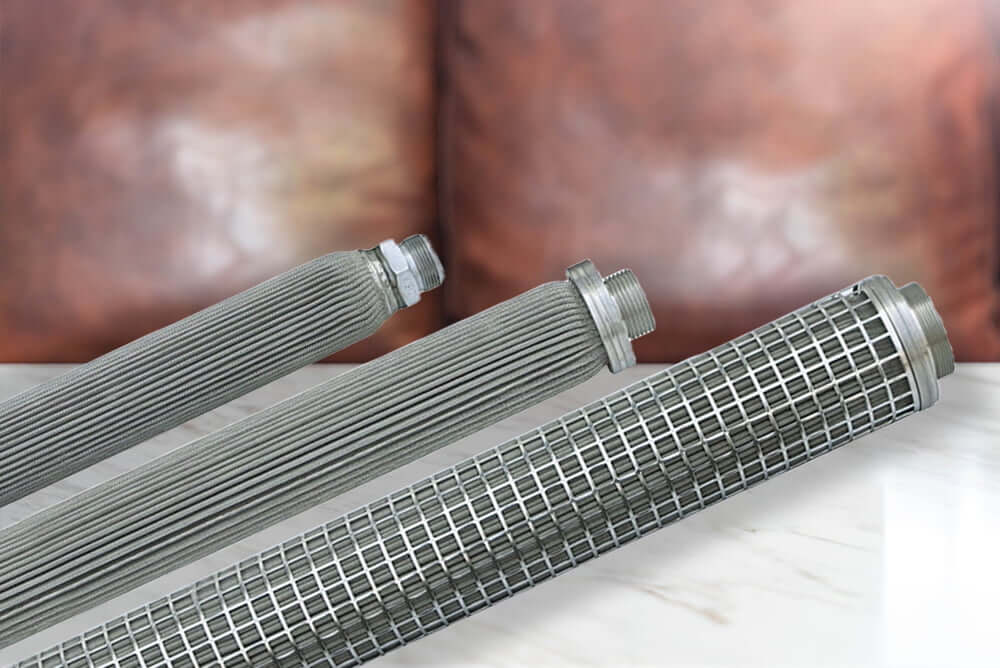

PP wound filter cartridges (Polypropylene) are made by tightly winding continuous polypropylene filaments around a core, typically made from stainless steel or polypropylene. This structure results in a depth filter that captures and removes particles, sediments, and impurities from liquids and gases as they pass through multiple layers of filtration media.

Due to the flexible construction and fine polypropylene material, these cartridges offer outstanding dirt-holding capacity and high efficiency in filtering particles of various sizes.

2. What is Filter Housing?

Filter housing is the casing or container that holds the filter cartridges. It provides structural support, protects the filter from environmental damage, and ensures that filtration is performed optimally by maintaining the correct flow of liquids or gases through the filter media. Quality filter housing is typically made from durable materials like stainless steel, aluminium, or high-strength plastic, ensuring long-lasting performance and compatibility with different types of filter cartridges.

3. Advantages of PP Wound Filter Cartridges

a) Excellent Filtration Efficiency

PP wound filter cartridges provide superior filtration efficiency due to their multi-layered design. The depth of the wound layers ensures that particles of different sizes are trapped within the various layers, resulting in effective filtration for a wide range of applications. They are particularly effective in capturing sediments, rust, and other impurities that may be present in liquids or gases.

b) High Dirt-Holding Capacity

Due to the multi-layered structure, PP wound filter cartridges have a high dirt-holding capacity compared to other types of filter cartridges. This means they can operate longer before needing replacement, making them ideal for environments where high particulate loads are present. This also results in lower maintenance costs and improved system longevity.

c) Wide Chemical Compatibility

One of the greatest advantages of PP wound filter cartridges is their chemical compatibility. Polypropylene is a highly versatile material, resistant to most acids, alkalis, and organic solvents. This makes PP wound cartridges suitable for a variety of industrial processes, including those involving aggressive chemicals or corrosive environments.

d) Cost-Effectiveness

PP wound filter cartridges offer an excellent cost-performance ratio. They are inexpensive to produce, making them affordable for large-scale operations while maintaining high filtration efficiency. Their long life and low maintenance needs further enhance their cost-effectiveness, making them a great choice for budget-conscious industries.

4. The Role of Quality Filter Housing

While PP wound filter cartridges are essential for effective filtration, their performance can only be optimized when paired with quality filter housing. Here’s why quality filter housing is crucial for your filtration system:

a) Durability and Longevity

Quality filter housing, made from materials like stainless steel or reinforced plastic, provides the necessary durability to withstand extreme operating conditions, including high pressure, temperature variations, and exposure to aggressive chemicals. This ensures that your filtration system can handle demanding environments without frequent breakdowns or repairs.

b) Leak-Proof Sealing

A major benefit of high-quality filter housing is its leak-proof sealing capabilities. Poor-quality housing can result in fluid bypass, where contaminated liquids or gases leak past the filter cartridge, reducing filtration efficiency. Quality filter housings are designed to create a tight seal around the filter cartridge, ensuring that all fluid passes through the filter media without leakage.

c) Customization Options

Quality filter housings are available in various sizes, shapes, and materials to fit different industrial needs. Whether you’re working in a high-pressure environment or handling hazardous chemicals, filter housings can be customized to meet specific operational requirements. This flexibility ensures that your filtration system performs optimally in any application.

d) Easy Installation and Maintenance

Top-notch filter housings are designed for easy installation and maintenance. Many high-quality housings feature simple designs that allow for quick cartridge replacements and minimal downtime. This is particularly important in industries where continuous operation is critical, such as water treatment plants and food processing facilities.

5. How PP Wound Filter Cartridges and Quality Filter Housing Work Together

The combination of PP wound filter cartridges and quality filter housing creates a powerful filtration system that provides the following key benefits:

a) Enhanced Filtration Performance

When PP wound filter cartridges are installed in quality filter housing, the system ensures that every drop of liquid or every bit of gas is effectively filtered. The multi-layered filtration offered by the cartridges, combined with the secure containment of the housing, leads to superior filtration performance and cleaner output.

b) Longer System Lifespan

A filtration system that uses both PP wound filter cartridges and durable filter housing is built for long-term operation. The high dirt-holding capacity of the cartridges, combined with the corrosion-resistant and leak-proof qualities of the housing, ensures that the system can run for extended periods with minimal maintenance and replacements.

c) Reduced Operating Costs

Industries that use PP wound filter cartridges and quality filter housing benefit from reduced operating costs. The affordable cartridges, long lifespan, and easy maintenance of the filter housing all contribute to lowering overall operational expenses. These savings can be particularly significant in large-scale industrial processes where filtration is continuous.

6. Applications of PP Wound Filter Cartridges and Filter Housing

PP wound filter cartridges and quality filter housing are widely used in various industries, including:

- Water Treatment: Filtration of sediments and impurities in municipal and industrial water systems.

- Food and Beverage: Removal of contaminants in food processing, breweries, and beverage production.

- Pharmaceuticals: Ensuring the purity of liquids and gases in pharmaceutical manufacturing.

- Chemical Processing: Filtration of aggressive chemicals and solvents.

- Oil and Gas: Purification of fuels and oils in upstream and downstream operations.

Conclusion

PP wound filter cartridges, when paired with quality filter housing, provide a highly efficient, durable, and cost-effective solution for industrial filtration. Their multi-layered design offers superior filtration efficiency and high dirt-holding capacity, while quality filter housing ensures durability, leak-proof performance, and easy maintenance. Together, they form a powerful combination that enhances the performance of filtration systems across various industries.

By choosing PP wound filter cartridges and quality filter housing, industries can improve their operational efficiency, reduce maintenance costs, and ensure long-term filtration system reliability.