A Legacy Of Quality

Define Filtration Inc. has built its reputation on a foundation of uncompromising quality. From the selection of raw materials to the final inspection of finished products, every step in the manufacturing process is governed by strict quality control measures. The company’s state-of-the-art facilities are equipped with advanced testing and inspection equipment to ensure that each filter cartridge meets or exceeds industry standards.

Rigorous Quality Control

At Define Filtration Inc., quality control is more than just a process; it’s a culture. The company employs a team of highly skilled engineers and technicians who meticulously oversee every aspect of production. Each filter cartridge undergoes a series of rigorous tests to evaluate its performance, durability, and reliability. This commitment to quality ensures that customers receive products that deliver consistent and dependable results.

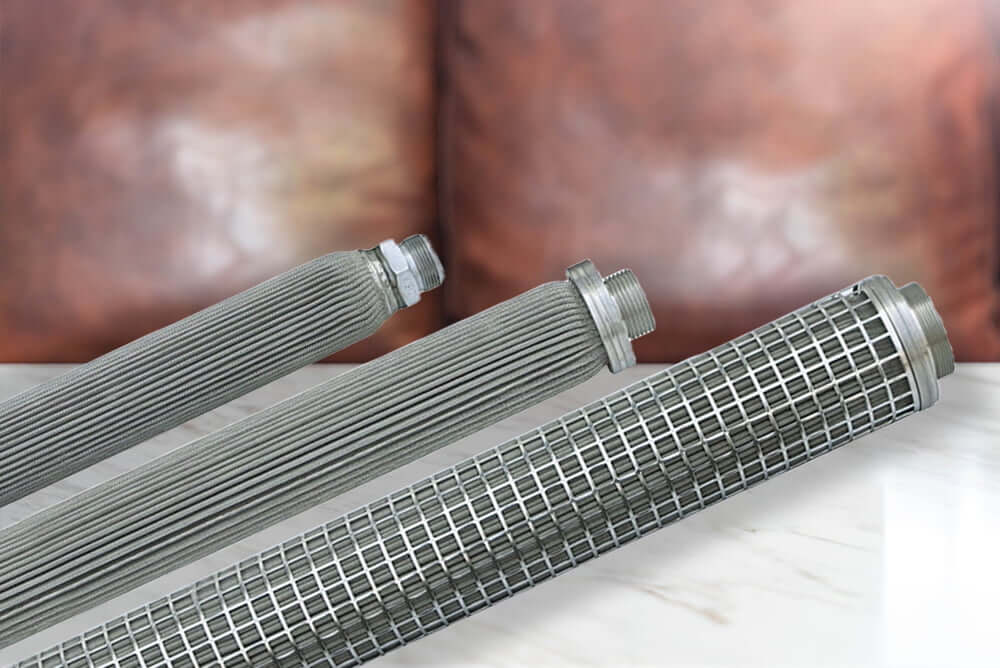

Premium Materials

The use of premium materials is another hallmark of Define Filtration Inc.’s filter cartridges. The company sources high-grade materials from trusted suppliers to ensure that every component of the filter cartridge is of the highest quality. This attention to detail translates into filter cartridges that offer superior filtration efficiency, longer service life, and reduced maintenance requirements.

Innovation At The Core

While quality is a cornerstone of Define Filtration Inc.’s success, innovation drives the company’s vision for the future. The company invests heavily in research and development to stay ahead of industry trends and meet the evolving needs of its customers. This dedication to innovation has resulted in a range of cutting-edge filtration solutions that set Define Filtration Inc. apart from its competitors.

Advanced Filtration Technology

Define Filtration Inc. is at the forefront of developing advanced filtration technologies that enhance the performance of its filter cartridges. The company’s R&D team collaborates with leading experts in the field to create innovative designs and materials that improve filtration efficiency and reduce operational costs. These advancements enable Define Filtration Inc. to offer filter cartridges that are not only effective but also economical.

Custom Solutions

Recognizing that every application has unique filtration requirements, Define Filtration Inc. offers custom solutions tailored to meet specific customer needs. The company’s experienced engineers work closely with clients to design and manufacture filter cartridges that address their particular challenges. This personalized approach ensures that customers receive filtration solutions that are optimized for their specific processes.

Commitment To Sustainability

In addition to quality and innovation, Define Filtration Inc. is deeply committed to sustainability. The company recognizes the importance of minimizing its environmental impact and has implemented several initiatives to promote eco-friendly practices throughout its operations.

Eco-Friendly Products

Define Filtration Inc. offers a range of eco-friendly filter cartridges designed to reduce waste and energy consumption. These products are made from sustainable materials and are engineered to provide long-lasting performance, thereby minimizing the need for frequent replacements. By choosing Define Filtration Inc.’s eco-friendly filter cartridges, customers can reduce their environmental footprint without compromising on quality or efficiency.

Sustainable Manufacturing Practices

The company’s commitment to sustainability extends beyond its products to its manufacturing practices. Define Filtration Inc. has implemented energy-efficient processes and waste reduction initiatives to minimize its environmental impact. The company continually seeks ways to improve its sustainability efforts and reduce its carbon footprint, ensuring a greener future for generations to come.

Customer-Centric Approach

Define Filtration Inc.’s success is built on its unwavering commitment to customer satisfaction. The company strives to exceed customer expectations by providing exceptional service and support at every stage of the customer journey.

Comprehensive Support

From initial consultation to after-sales service, Define Filtration Inc. offers comprehensive support to its customers. The company’s knowledgeable and responsive customer service team is always available to answer questions, provide technical assistance, and offer guidance on product selection and maintenance. This dedication to customer care ensures that clients receive the support they need to achieve optimal filtration performance.

Training And Education

Define Filtration Inc. believes in empowering its customers with the knowledge and skills they need to make informed decisions about their filtration systems. The company offers training programs and educational resources to help customers understand the principles of filtration and the benefits of Define Filtration Inc.’s products. These initiatives not only enhance customer satisfaction but also foster long-term partnerships built on trust and mutual success.

Define Filtration Inc. stands as a beacon of quality and innovation in the filtration industry. With its unwavering commitment to excellence, advanced filtration technologies, sustainable practices, and customer-centric approach, the company continues to set new standards for filter cartridges. Whether you need reliable filtration solutions for industrial applications or custom-designed filter cartridges for specialized processes, Define Filtration Inc. is your trusted partner for superior filtration performance.