In the world of industrial filtration, selecting the right filtration method is crucial for ensuring the purity and quality of liquids. One widely-used option is the wound filter cartridge, known for its versatility and efficiency. In this blog, we’ll delve into a comparative analysis, pitting wound filter cartridges against other filtration methods to better understand their unique advantages and limitations.

Understanding Filtration Methods

Before diving into the comparisons, it’s essential to grasp the basic principles of different filtration methods. Wound filter cartridges belong to the depth filtration category, trapping particles within the filter matrix as fluid passes through. Now, let’s explore how they stack up against other popular methods:

1. Wound Filter Cartridges Vs. Membrane Filtration: Precision And Pore Size

Wound Filter Cartridges: These cartridges excel in applications where a broader range of particle sizes needs to be captured. Their fibrous matrix can trap both large and small particles effectively.

Membrane Filtration: Membrane filters, on the other hand, offer precise control over particle size. They are ideal for applications requiring the removal of specific contaminants with a defined pore size.

2. Wound Filter Cartridges Vs. Activated Carbon Filtration: Versatility And Adsorption

Wound Filter Cartridges: The versatility of wound filter cartridges shines in their ability to handle a variety of liquids, from water to chemicals. They’re especially adept at removing sediment and larger particulate matter.

Activated Carbon Filtration: Activated carbon is known for its adsorption capabilities, making it an excellent choice for removing organic impurities, odors, and color. However, it may not be as effective in capturing larger particles.

3. Wound Filter Cartridges Vs. Bag Filters: Efficiency And Surface Area

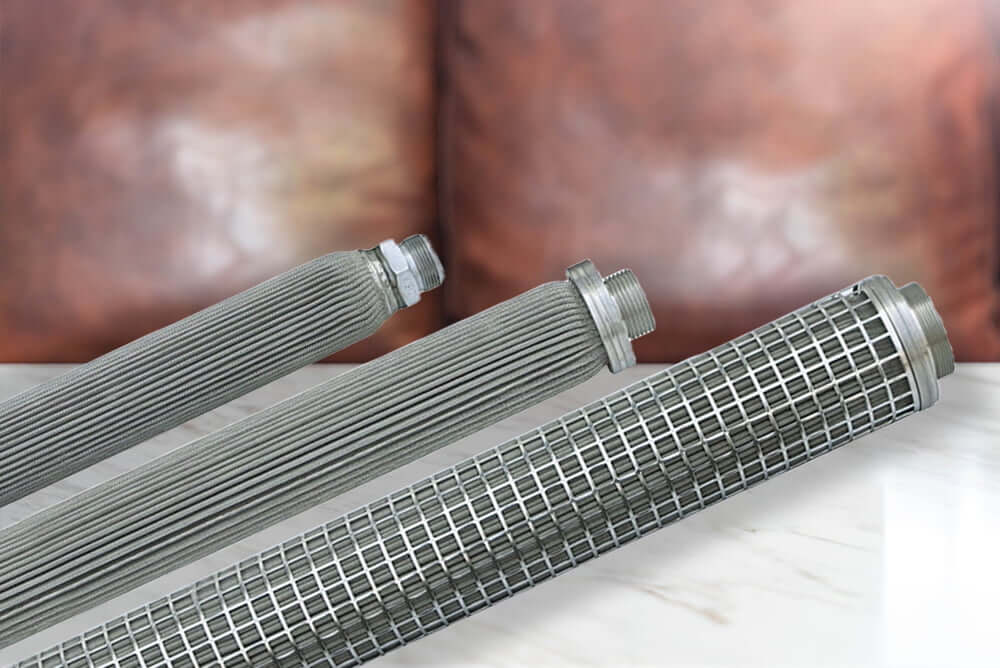

Wound Filter Cartridges: These cartridges boast a high filtration surface area due to their coiled structure, allowing for extended service life and efficient particle capture. They are suitable for both pre-filtration and final filtration stages.

Bag Filters: Bag filters, while effective, may have a lower surface area compared to wound filter cartridges. This can result in more frequent replacements and higher operating costs in certain applications.

4. Wound Filter Cartridges Vs. Diatomaceous Earth (DE) Filtration: Clarity And Flow Rate

Wound Filter Cartridges: With their graded density structure, wound filter cartridges maintain a steady flow rate while providing consistent filtration performance. They are well-suited for applications where a constant flow is critical.

Diatomaceous Earth Filtration: DE filtration is known for achieving high levels of clarity by removing very fine particles. However, the process can be slower, and DE filtration systems may require more maintenance.

Choosing The Right Tool For The Job

In the realm of filtration, there’s no one-size-fits-all solution. Each method has its strengths and weaknesses, and the choice depends on specific application requirements. Wound filter cartridges stand out for their versatility, efficiency, and cost-effectiveness, making them a preferred choice in various industries. By understanding the nuances of different filtration methods, businesses can make informed decisions that align with their unique needs, ensuring the purity and quality of their processes.