In the world of industrial filtration, innovation and reliability are paramount. Companies across various sectors rely on effective filtration solutions to ensure the purity of their processes, the quality of their products, and the safety of their operations. Define Filtration Inc., a leading manufacturer in the filtration industry, stands out by offering state-of-the-art wound filter cartridge solutions. These products are designed to meet the rigorous demands of various industries, providing unmatched performance and durability. In this blog, we will delve into the innovative features, benefits, and applications of wound filter cartridges by Define Filtration Inc.

The Science Behind Wound Filter Cartridges

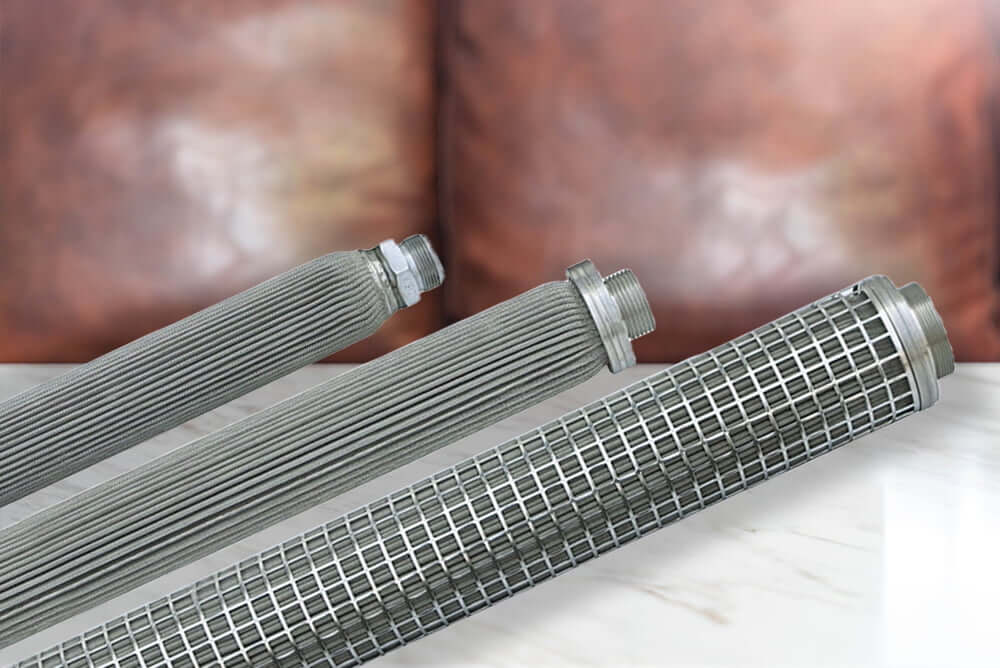

Wound filter cartridges are constructed by winding a continuous strand of material around a central core. This design creates a gradient density structure, which provides superior filtration efficiency and dirt-holding capacity. The unique manufacturing process ensures that the cartridges can capture particles of varying sizes, making them ideal for a wide range of applications.

Define Filtration Inc. utilizes advanced materials and precision engineering to produce wound filter cartridges that excel in performance. The company offers a variety of materials, including polypropylene, cotton, and glass fiber, to suit different filtration needs. Each material is selected based on its compatibility with the fluid being filtered and the specific requirements of the application.

Key Features of Define Filtration Inc.’s Wound Filter Cartridges

Define Filtration Inc. has integrated several innovative features into their wound filter cartridges, setting them apart from competitors. Here are some key features:

1. High Dirt-Holding Capacity: The gradient density structure of Define Filtration Inc.’s wound filter cartridges allows for efficient particle capture. This design maximizes dirt-holding capacity, reducing the frequency of cartridge replacement and lowering operational costs.

2. Wide Chemical Compatibility: With a range of material options, Define Filtration Inc.’s wound filter cartridges are compatible with various chemicals and fluids. This versatility makes them suitable for applications in the food and beverage, pharmaceutical, chemical, and water treatment industries.

3. Customizable Options: Define Filtration Inc. understands that different applications have unique requirements. They offer customizable wound filter cartridges in terms of length, diameter, and micron ratings. This flexibility ensures that customers receive a filtration solution tailored to their specific needs.

4. High Flow Rates: The design of the wound filter cartridges promotes high flow rates while maintaining excellent filtration efficiency. This feature is particularly important in applications where maintaining optimal flow is crucial for operational efficiency.

5. Thermal Stability: Certain industrial applications involve high temperatures. Define Filtration Inc.’s wound filter cartridges are designed to withstand elevated temperatures, ensuring consistent performance even in demanding environments.

Benefits of Using Define Filtration Inc.’ Wound Filter Cartridges

Choosing Define Filtration Inc.’s wound filter cartridges offers numerous benefits to businesses across various industries. Here are some of the key advantages:

1. Enhanced Filtration Efficiency: The gradient density structure of the wound filter cartridges ensures effective removal of contaminants, resulting in cleaner fluids and improved product quality.

2. Cost-Effective Solutions: With their high dirt-holding capacity and durability, Define Filtration Inc.’s wound filter cartridges reduce the need for frequent replacements. This translates to lower maintenance costs and increased operational efficiency.

3. Versatility: Define Filtration Inc.’s wound filter cartridges can be used in a wide range of applications, from water treatment to chemical processing. Their compatibility with different fluids and chemicals makes them a versatile choice for various industries.

4. Customization: The ability to customize wound filter cartridges ensures that customers receive a product that meets their specific requirements. This customization enhances the overall efficiency and effectiveness of the filtration process.

5. Reliable Performance: Define Filtration Inc. is committed to delivering high-quality products that consistently perform well. Their wound filter cartridges are designed to provide reliable and long-lasting filtration solutions.

Applications of Define Filtration Inc.’s Wound Filter Cartridges

Define Filtration Inc.’s wound filter cartridges are used in a multitude of applications across various industries. Some of the key applications include:

1. Water Treatment: In the water treatment industry, wound filter cartridges are essential for removing sediments, particles, and impurities from water. They are used in both municipal and industrial water treatment processes to ensure the supply of clean and safe water.

2. Food and Beverage: The food and beverage industry requires stringent filtration standards to maintain product quality and safety. Define Filtration Inc.’s wound filter cartridges are used to filter liquids such as syrups, oils, and beverages, ensuring the removal of contaminants and impurities.

3. Pharmaceutical: In pharmaceutical manufacturing, maintaining the purity of fluids is critical. Wound filter cartridges by Define Filtration Inc. are used to filter solvents, reagents, and other fluids, ensuring compliance with strict industry standards.

4. Chemical Processing: The chemical industry often deals with aggressive and corrosive fluids. Define Filtration Inc.’s wound filter cartridges, with their wide chemical compatibility, are ideal for filtering various chemicals and ensuring the purity of the end products.

5. Oil and Gas: In the oil and gas industry, filtration is crucial for removing contaminants from process fluids and ensuring the smooth operation of equipment. Wound filter cartridges by Define Filtration Inc. are used in various stages of oil and gas processing to achieve optimal filtration results.

Commitment to Quality and Innovation

Define Filtration Inc. has built a reputation for excellence through their commitment to quality and innovation. Their wound filter cartridges undergo rigorous testing and quality control to ensure they meet the highest standards. The company’s focus on research and development enables them to continuously improve their products and introduce new solutions to meet evolving industry needs.

By investing in cutting-edge technology and adhering to stringent quality standards, Define Filtration Inc. has established itself as a trusted name in the filtration industry. Their wound filter cartridges exemplify their dedication to providing innovative and reliable filtration solutions.

Conclusion

In conclusion, Define Filtration Inc.’s wound filter cartridges offer a combination of innovative design, superior performance, and versatility. These filtration solutions are engineered to meet the diverse needs of various industries, ensuring effective removal of contaminants and impurities. With a commitment to quality and a focus on continuous improvement, Define Filtration Inc. stands out as a leader in the manufacturing of wound filter cartridges. Businesses looking for reliable and efficient filtration solutions can confidently choose Define Filtration Inc.’s wound filter cartridges to enhance their operations and achieve optimal results.

No comments:

Post a Comment