In the world of industrial filtration, the importance of high-quality filter housing cannot be overstated. It is the backbone of efficient filtration systems, ensuring that contaminants are effectively removed from liquids and gasses. When it comes to choosing the best filter housing manufacturer and supplier, there are several key factors to consider. In this blog post, we will explore the qualities that make a manufacturer stand out and provide you with insights into finding the best supplier for your filtration needs.

Why Filter Housing Matters

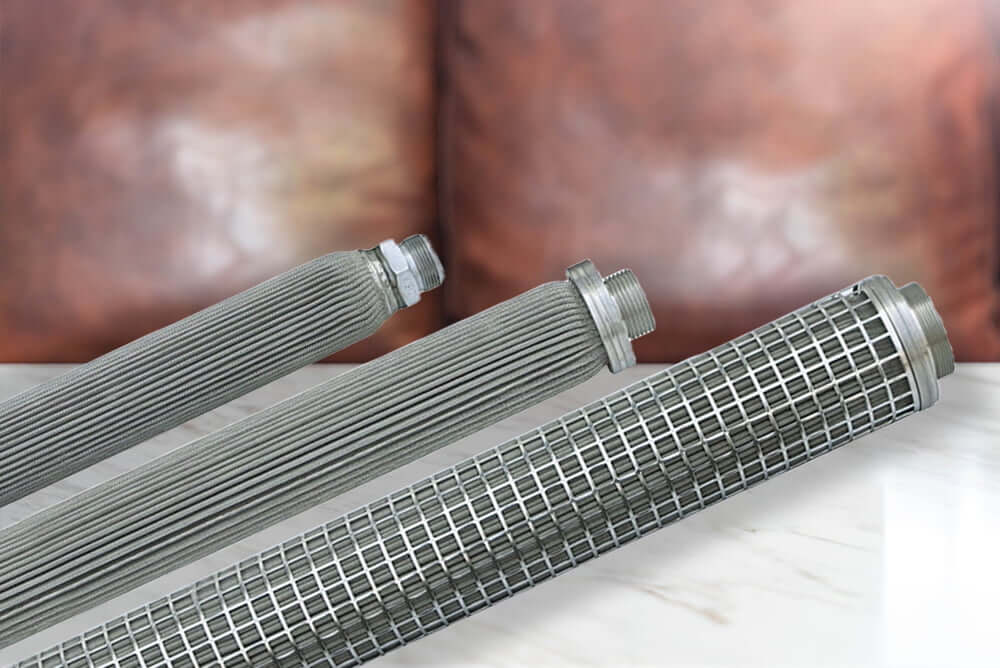

Filter housing plays a critical role in the filtration process. It provides a protective casing for the filter element, ensuring that it remains intact and functional. Additionally, filter housing helps to maintain the integrity of the filtration system, preventing leaks and ensuring that contaminants are properly contained.

Qualities of a Top-tier Manufacturer

When it comes to choosing a filter housings manufacturer, quality should be your top priority. A top-tier manufacturer will have a reputation for producing high-quality products that meet industry standards. Look for manufacturers that use premium materials, such as stainless steel or aluminum, which offer durability and corrosion resistance.

Another important factor to consider is the manufacturer’s expertise and experience in the field. A manufacturer with a long history of producing filter housings is likely to have a deep understanding of the industry and the needs of their customers. They will also be more likely to have the resources and expertise to develop innovative solutions to meet evolving filtration challenges.

Choosing the Best Supplier

In addition to choosing the right manufacturer, it is also important to select the best supplier for your filter housing needs. Look for suppliers that offer a wide range of products to choose from, ensuring that you can find the perfect housing for your filtration system. Additionally, consider suppliers that offer customization options, allowing you to tailor the housing to meet your specific requirements.

Reliability is another key factor to consider when choosing a supplier. Look for suppliers that have a reputation for delivering products on time and that offer excellent customer service. A reliable supplier will be able to provide you with the support you need to ensure that your filtration system operates smoothly and efficiently.

When it comes to filter housing excellence, choosing the right manufacturer and supplier is key. By selecting a manufacturer with a reputation for quality and a supplier that offers reliability and support, you can ensure that your filtration system operates at its best. So, whether you are in need of a new filter housings or are looking to upgrade your existing system, be sure to consider these factors to find the best manufacturer and supplier for your needs.