Filter cartridges are essential components in various filtration systems, ensuring the removal of contaminants and improving the quality of water, air, and other fluids. Choosing the right filter cartridge can significantly impact the efficiency and effectiveness of your filtration system. In this comprehensive guide, we will explore the different types of filter cartridges, their applications, and the benefits of each type to help you determine which one is best for your needs.

Types of Filter Cartridges

- Pleated Filter Cartridges

- Carbon Block Filter Cartridges

- Ceramic Filter Cartridges

- String Wound Filter Cartridges

- Membrane Filter Cartridges

- Resin-Bonded Filter Cartridges

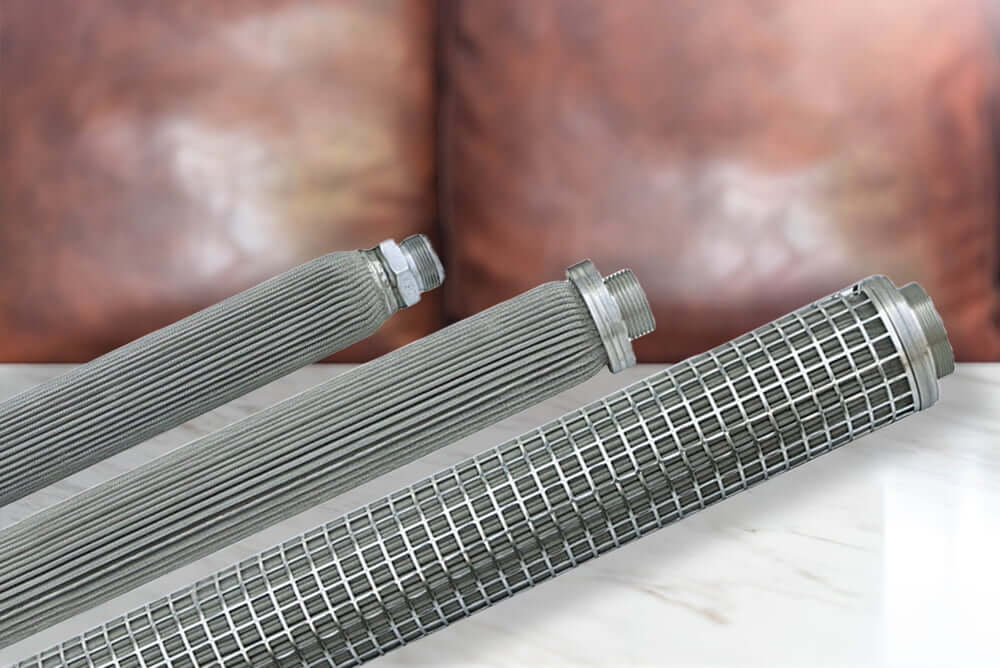

1. Pleated Filter Cartridges

Pleated filter cartridges are made from a variety of materials, including polyester, polypropylene, and cellulose. These cartridges are characterized by their pleated design, which provides a large surface area for filtration.

Benefits of Pleated Filter Cartridges:

- High Dirt-Holding Capacity: The pleated design allows for a larger surface area, which means they can hold more contaminants before needing replacement.

- Reusable and Washable: Many pleated filters can be cleaned and reused, making them a cost-effective option over time.

- Versatility: Suitable for various applications, including water and air filtration.

2. Carbon Block Filter Cartridges

Carbon block filter cartridges are made from activated carbon that has been compressed into a solid block. These cartridges are highly effective at removing chlorine, volatile organic compounds (VOCs), and other impurities.

Benefits of Carbon Block Filter Cartridges:

- Excellent Contaminant Removal: Effective at removing chlorine, taste, odor, and organic compounds.

- Improves Taste and Odor: Particularly useful in water filtration, enhancing the taste and smell of drinking water.

- Chemical Absorption: The activated carbon material absorbs a wide range of chemicals and impurities.

3. Ceramic Filter Cartridges

Ceramic filter cartridges are made from natural ceramic materials and are known for their ability to remove bacteria, cysts, and other microorganisms from water.

Benefits of Ceramic Filter Cartridges:

- Effective Against Microorganisms: Highly efficient at removing bacteria, cysts, and other pathogens.

- Long-Lasting and Durable: Ceramic filters can be cleaned and reused, offering a long lifespan.

- Natural Filtration: Made from natural materials, providing an eco-friendly filtration option.

4. String Wound Filter Cartridges

String wound filter cartridges are constructed by winding a string around a core. These cartridges are typically used for sediment filtration.

Benefits of String Wound Filter Cartridges:

- High Sediment Removal: Effective at capturing large particles and sediment from fluids.

- Customizable Micron Ratings: Available in various micron ratings to suit different filtration needs.

- Cost-Effective: Generally less expensive compared to other types of filter cartridges.

5. Membrane Filter Cartridges

Membrane filter cartridges use semi-permeable membranes to remove fine particles and microorganisms from fluids. They are commonly used in reverse osmosis systems.

Benefits of Membrane Filter Cartridges:

- High Precision Filtration: Capable of removing very small particles, including viruses and bacteria.

- Versatile Applications: Used in water purification, medical, and industrial applications.

- Efficient Contaminant Removal: Provides a high level of purification for various fluids.

6. Resin-Bonded Filter Cartridges

Resin-bonded filter cartridges are made by bonding resin to fibers, creating a rigid and durable filter medium. These cartridges are used for both water and chemical filtration.

Benefits of Resin-Bonded Filter Cartridges:

- Chemical Resistance: Suitable for filtering aggressive chemicals and solvents.

- Rigid Structure: Offers durability and can withstand high-pressure applications.

- High Flow Rates: Allows for efficient filtration without significant pressure drops.

Choosing the Right Filter Cartridge

Selecting the appropriate filter cartridge depends on several factors, including the type of contaminants you need to remove, the application, and the specific requirements of your filtration system. Here are some key considerations to help you make an informed decision:

- Identify Contaminants: Determine the specific contaminants you need to remove from your fluid. This could include sediment, chlorine, bacteria, chemicals, or other impurities.

- Application: Consider the application of your filtration system. For example, water filtration may require different cartridges compared to air or chemical filtration.

- Micron Rating: The micron rating of a filter cartridge indicates the size of particles it can remove. Choose a cartridge with the appropriate micron rating for your needs.

- Flow Rate: Ensure that the filter cartridge can handle the required flow rate of your system without causing significant pressure drops.

- Maintenance and Replacement: Consider the maintenance requirements and lifespan of the filter cartridge. Some cartridges are reusable and washable, while others need regular replacement.

- Compatibility: Ensure that the filter cartridge is compatible with your filtration system. Check the dimensions, connections, and other specifications to avoid compatibility issues.

Conclusion

Understanding the different types of filter cartridges and their benefits is crucial for optimizing the performance of your filtration system. Whether you need to remove sediment, chemicals, microorganisms, or other contaminants, there is a filter cartridge designed to meet your specific needs. By carefully considering the type of contaminants, application, micron rating, flow rate, maintenance requirements, and compatibility, you can choose the best filter cartridge for your system. This will ensure efficient filtration, improved fluid quality, and a longer lifespan for your filtration equipment.