Filter cartridges play a crucial role in various industries, ensuring both water quality and the longevity of equipment. Whether in industrial settings, households, or commercial applications, filter cartridges are essential for removing impurities and protecting machinery from damage. This article explores the ways in which filter cartridges enhance water quality and extend the life of equipment, making them indispensable components in many systems.

The Importance of Water Quality

Water quality is a critical factor in numerous applications. Poor water quality can lead to several issues, including health risks, operational inefficiencies, and equipment damage. Contaminants such as dirt, rust, chemicals, and microorganisms can compromise water quality, making it essential to have effective filtration systems in place.

Health and Safety

One of the primary reasons for using filter cartridges is to ensure water is safe for consumption and use. Contaminated water can cause various health problems, including gastrointestinal issues, skin irritations, and more severe conditions like lead poisoning. By removing harmful substances, filter cartridges help provide clean, safe water for drinking, cooking, and other uses.

Operational Efficiency

In industrial settings, water quality can significantly impact the efficiency of processes. Contaminants in water can cause scaling, fouling, and corrosion in equipment, leading to decreased performance and increased maintenance needs. High-quality filter cartridges help maintain operational efficiency by keeping water clean and free from harmful substances.

How Filter Cartridges Work

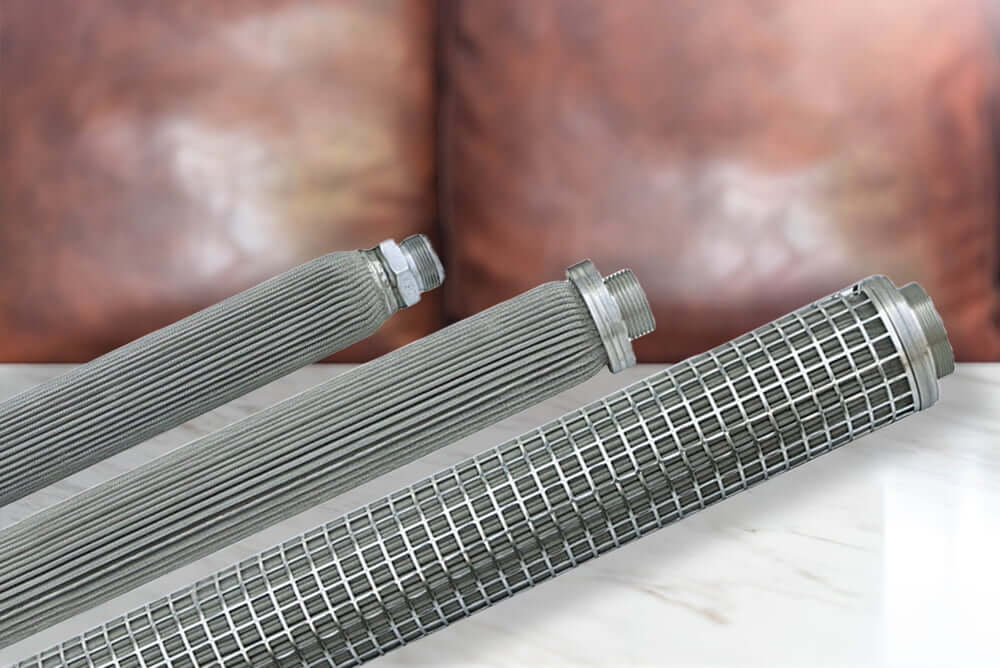

Filter cartridges function by trapping contaminants and particles as water passes through them. They come in various types, each designed to target specific impurities. Some of the common types of filter cartridges include:

Sediment Filter Cartridges

These cartridges are designed to remove larger particles such as sand, silt, dirt, and rust. They are typically used as pre-filters to protect more sensitive filtration systems and equipment from damage caused by larger debris.

Activated Carbon Filter Cartridges

Activated carbon cartridges are highly effective at removing organic compounds, chlorine, and other chemicals that can affect taste and odor. They work by adsorbing contaminants onto the surface of the carbon particles, ensuring cleaner and better-tasting water.

Reverse Osmosis (RO) Filter Cartridges

RO filter cartridges use a semi-permeable membrane to remove a wide range of impurities, including dissolved salts, bacteria, and viruses. They are often used in applications requiring high-purity water, such as in medical and industrial processes.

Ultraviolet (UV) Filter Cartridges

UV filter cartridges use ultraviolet light to kill or inactivate microorganisms, providing an additional layer of protection against bacteria and viruses. They are commonly used in conjunction with other filtration methods to ensure comprehensive water treatment.

Extending Equipment Life with Filter Cartridges

In addition to improving water quality, filter cartridges play a vital role in extending the life of equipment. By preventing contaminants from entering and accumulating in machinery, they help reduce wear and tear, minimize maintenance needs, and avoid costly repairs.

Preventing Scale and Corrosion

One of the significant ways filter cartridges protect equipment is by preventing scale and corrosion. Scale, a hard, mineral-rich deposit, can form on surfaces and inside pipes when water contains high levels of dissolved minerals. This can lead to reduced efficiency, increased energy consumption, and even equipment failure. Corrosion, on the other hand, can weaken metal components, leading to leaks and structural damage. By removing these minerals and other corrosive substances, filter cartridges help maintain the integrity and performance of equipment.

Reducing Fouling and Clogging

Fouling occurs when contaminants accumulate on surfaces, leading to blockages and reduced flow rates. This can be particularly problematic in heat exchangers, boilers, and other systems that rely on consistent water flow. Filter cartridges trap particles and prevent them from building up inside equipment, ensuring smooth operation and reducing the risk of clogs.

Protecting Sensitive Components

Many types of equipment have sensitive components that can be easily damaged by contaminants. For example, in reverse osmosis systems, the RO membrane can be damaged by chlorine and other chemicals. Similarly, in cooling systems, impurities can damage pumps, valves, and other critical parts. By providing clean water, filter cartridges help protect these sensitive components, extending their lifespan and reducing the need for replacements.

Choosing the Right Filter Cartridge

Selecting the appropriate filter cartridge for your needs is essential for achieving optimal results. Factors to consider include the type and concentration of contaminants, the desired water quality, and the specific requirements of your equipment. Consulting with a filtration expert can help you determine the best solution for your application.

Regular Maintenance and Replacement

To ensure continued effectiveness, it is important to perform regular maintenance and replace filter cartridges as needed. Over time, cartridges can become clogged with contaminants, reducing their efficiency. Following the manufacturer's recommendations for maintenance and replacement intervals will help ensure your filtration system continues to provide clean water and protect your equipment.

Conclusion

Filter cartridges are vital components in maintaining water quality and extending the life of equipment. By removing impurities and preventing damage caused by contaminants, they help ensure safe, efficient, and long-lasting operation in various applications. Investing in high-quality filter cartridges and performing regular maintenance can lead to significant benefits, including improved health and safety, operational efficiency, and cost savings.

No comments:

Post a Comment